Description

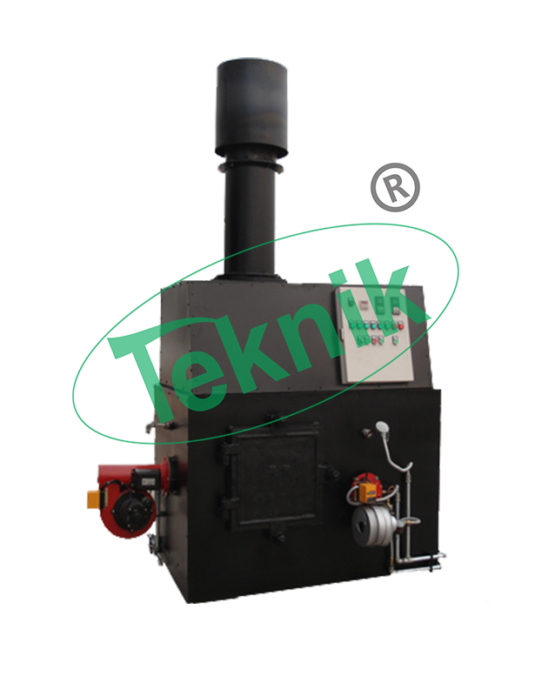

Incineration uses combustion to make infectious industrial waste harmless and reduce the waste mass and volume by more than 90 percent. Proper incineration can convert certain wastes into gases and incombustible solid residues (e.g., ash) that are relatively harmless. A dual-chamber incinerator operated within the optimal temperature range of 850° to 1200°C results in a lower level of emissions. The gases from incineration are released into the atmosphere (with or without gas cleaning). Residue ash from proper incineration can be encapsulated in designated ash pits or controlled landfills without any major risk. However, when the conditions are not adequate—for example, when the waste is not properly segregated or the incinerator is not properly constructed or operated—toxic compounds can be found in the unburned waste, and harmful gases can be released into the atmosphere. Good planning, technical oversight, and sustained supportive supervision of incinerator systems are critical to ensuring safe incineration. Waste incineration plants is operated in such a way as to achieve a level of incineration such that the total organic carbon content of slag and bottom ashes is less than 3% or their loss on ignition is less than 5% of the dry weight of the material.

Why Industrial Incinerator?

- Waste reduction efficiency is 97% minimum.

- LPG, N-Gas, Diesel, Electrical can be used as fuel

- The system is equipped with optional automatic loading and ash removal mechanisms.

- Combustion efficiency is 99.99%

- Spare parts are easily accessed and maintenance is easy.

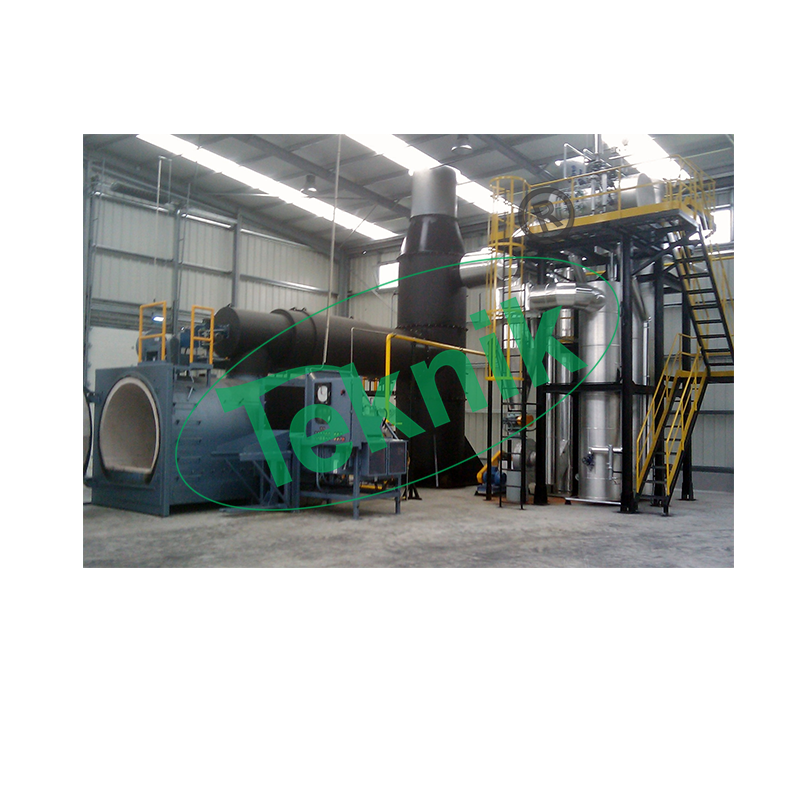

Industrial waste incinerator is incinerated organic, combustible materials and to convert these materials into harmless and disposable residual matter while fully complying with required environmental. In the combustion chamber, waste are incinerated at 850 – 1000 C based on the type of waste. Flue gases originated in the main combustion chamber are re-burnt with excess of 850-1200 C during 2 seconds in the post combustion chamber. In order to be fully in compliance with the desired emission standards, flue gas treatment units are included in Industrial waste incinerator. Flue gas treatment is based on multi pollutant control approach to remove the hazardous content of the combustion gases originated due to waste incineration.

Controlling System and Automation:

The entire incineration and scrubbing process is operated and controlled by a tamper proof PLC based fully automatic control panel. The sensors, safety interlocks and audio visual alarms installed in the system ensure a safe and trouble free operation. The motors are operated by variable frequency drives (VFD) installed in the control panel.

Industries We Serve:

- Packaging Industries

- Food processing Industries

- Cement Industries

- Pharmaceutical Industries

- Paint Shops

** Note:-The content of the product and specification are subject to change without prior notice for continuous improvement.