Description

Any plastic waste or scrap has to undergo the following steps to be considered for recycling:

Step 1: Sorting/Separation – Plastics are many different types and it must be separated into different types, plastic needs to be sorted after collection.

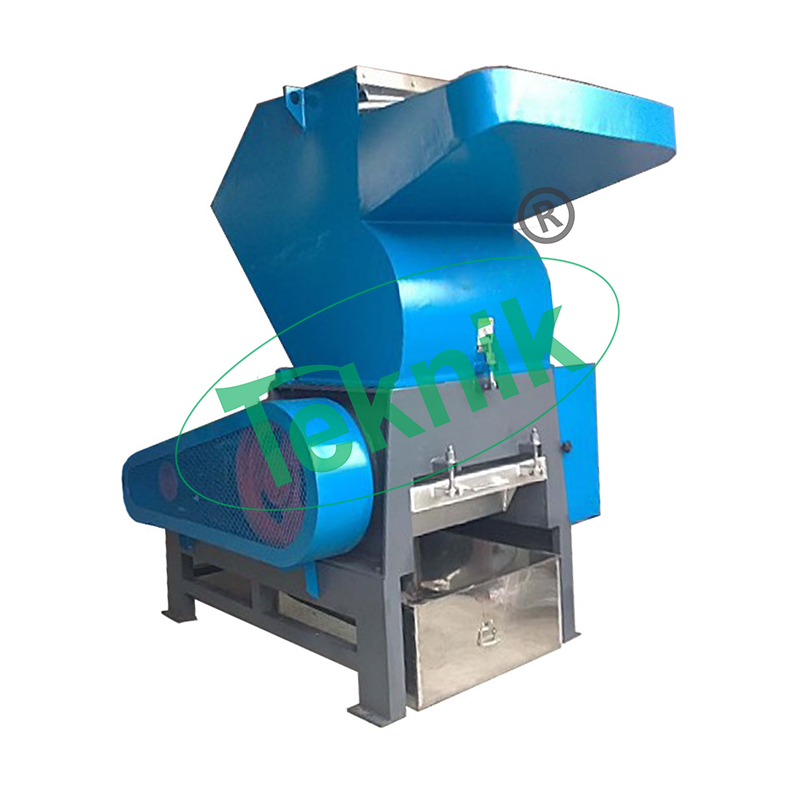

Step 2: Shredding – Once all the plastics are shorted from the waste plastic, the next step involves shredded them into pieces. Shredding is done by a variety of tools and equipment that is able to breakdown the waste plastic into small pellets.

Step 3: Extruding – The final stage is melting the plastic pellets on basic temperature which have been tested and approved. This is a process that involves a lot of energy consumption and must be done using specific equipment. After completion of this process the plastic can be recycled and used to manufacture other products.

Plastic recycling is helps to take care of our world by pollution due to burning by smoke and barren land by dump of garbage.

DESIGNED FOR PET AND HDPE

The Plastic Shredder is capable of processing over 900 lbs. of PET plastic per hour. A 24” PVC conveyor belt with 3” cleats carries the containers into a crushing chamber with a rotating steel drum. Knives on the drum puncture the plastic containers, discharging the plastic into a Gaylord box or baler.

APPLICATION:

- Finishing & Producing Industry

- Hospitals/Nursing homes

- Bio Medical Waste

- Laboratories

- Catering Industry

- Supermarkets

- Municipal Authorities

- Pharmaceutical Industry

- Plastic Industry

- Card Board Industry

** Note:-The content of the product and specification are subject to change without prior notice for continuous improvement.