Description

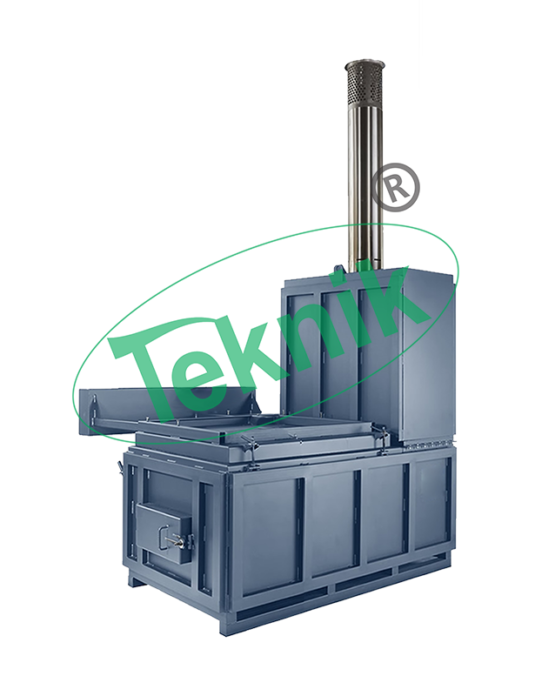

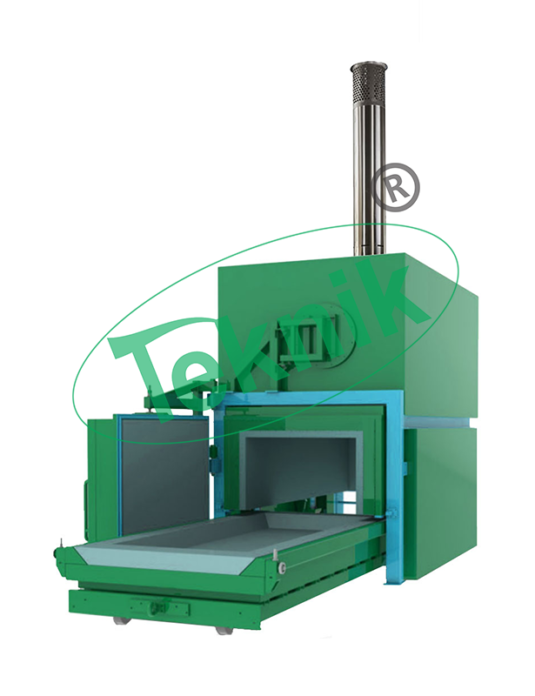

The bio medical waste Incinerator is one of the treatment and safe disposal of the bio-medical waste generated from the hospitals, veterinary facilities, medical research facilities etc.

These wastes include both infectious medical wastes as well as non-infectious, general housekeeping wastes.

Bio-medical incinerator stack emission standards which include for residence time of two sec. in secondary chamber.

Incineration and other high temperature waste treatment systems are described as “thermal treatment or destruction process”. Incineration of waste materials converts waste containing elements of carbon, hydrogen, oxygen along with presence of other elements such as nitrogen, sulphur, chlorine and pathogens etc., can be destroyed completely by oxidation process using auxiliary fuel producing benign gases (flue gases) such as carbon dioxide, water, and nitrogen and some acidic gases such as oxides of sulphur, nitrogen, acids and other toxic gases such as heavy metals, Dioxins & Furans etc. as well as solid form of ash, depending upon waste constituents of the waste and performance of incineration system.

The bio-medical waste incineration is designed for primary and secondary combustion systems. Total Organic carbon content in the slag/bottom ash is less than 3% or their loss on ignition is less than 5% of the dry weight as prescribed. Incinerator chambers are also fitted with a suitable provision of pressure gauges for measuring the air supply or flow rate. Combustion air measurement through flow transmitter is provided and display in Programmable Logical Control (PLC). The double chamber incinerator is preferably be designed on “controlled-air” incineration principle, as particulate matter emission is low in such incinerator. Air supply in the primary and secondary chamber may be regulated between 30%-80% and 170%-120% of stiochiometric requirement respectively. In primary chamber, primary air is admitted near. Flow meter / suitable flow measurement device is provided on the primary and secondary air ducting. The combustion air is supplied through a separate forced draft fan after accounting for the air supplied through burners. The primary chamber is to avoid leakage of gaseous emissions from the chamber and for safety reasons. Provision is made in the primary chamber to measure the Water Column pressure.

The secondary chamber is properly designed so as to facilitate a minimum of two seconds residence time to ensure combustion of the gas flow, unburnt material such as volatiles, smoke and soot. For the estimation of residence time in the secondary chamber its volume calculated starting from the secondary burner tip to the thermocouple. Incinerator walls are protected with insulated fire bricks/refractory system. The refractory lining of the chamber is strong enough to sustain thermal shocks i.e. minimum temperature 1000° C in the primary chamber and 1050° C + or – 50° C in the secondary chamber. The refractory & insulation brick is have suitable thickness. The minimum temperature of secondary chamber is 1200° C. The incinerator combustion chamber is designed for easy maintenance of all internal parts including refractory and isolation.

** Note:-The content of the product and specification are subject to change without prior notice for continuous improvement.